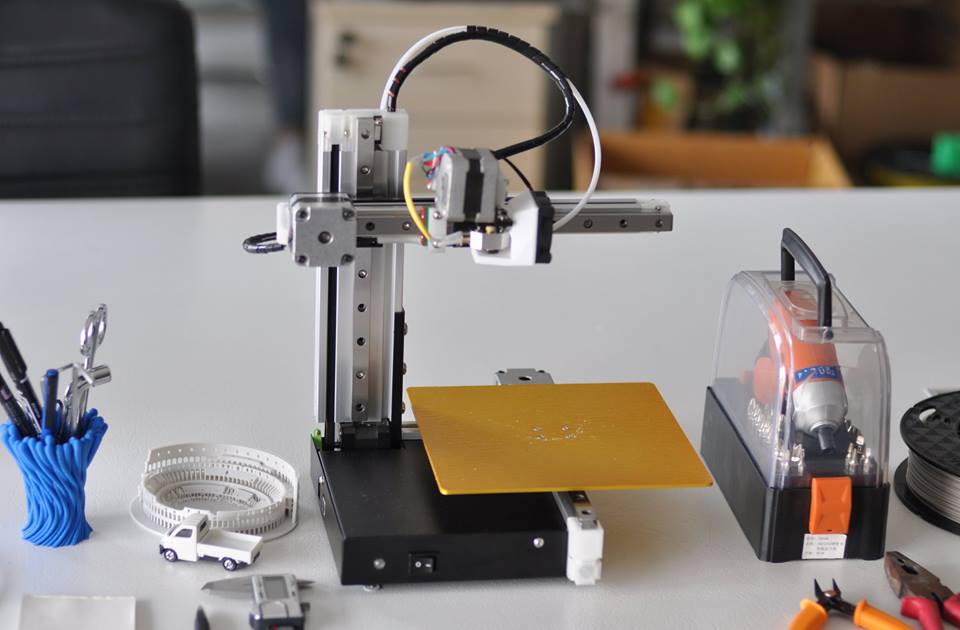

changed structural holes (larger hole -> smaller holes).I hesitated to use lead screws due decrease of resolution (M8: 1 cycle = 1.25mm height, lead screw like TR8x8 (8mm dia, 4 starts, 2mm pitch, 8mm lead => 1 cycle = 8mm height) but otherwise gaining pretty straight lead.Īnyway, I searched Thingiverse for Z mounts for the CTC DIY and found a few, and adapted one design and made a remix Geeetech / CTC Prusa i3 DIY – Z Axis Bracket Remix with printable Bearing :

#Cetus3d z banding pro

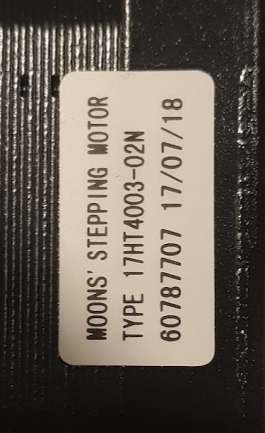

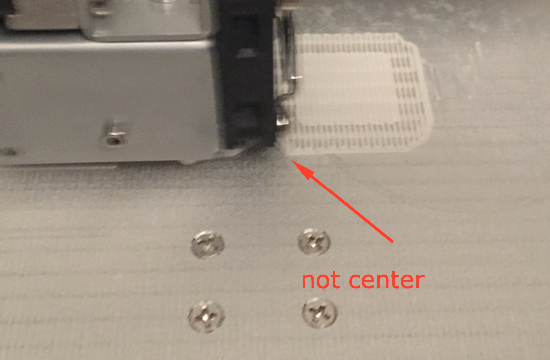

You can also do this through MakerBot Print: Navigate to the Printer Panel and select the printer whose Z Offset you wish to recalibrate.Using a low-cost 3D printer like CTC DIY I3 Pro B (Geeetech I3 Pro B clone) with M8 threaded rods as Z axis with loose or floating ends is what you get – and so also some wobble or banding on the X axis due slightly bent M8 threaded rods – they barely come straight. You can recalibrate the Z Offset directly on the printer by going to the printer's main menu and selecting Info > Calibration > Calibrate Z Offset. You can manually modify the offset in “Setting>More Settings>Hardware>Z Probe Offset”. On your printer's screen, tap “Setting>Maintenance>Offset Calibration”. You can use the calibration menu to automatically calibrate the Z-offset. What causes Z wobble?Īlthough Z wobble is commonly associated with a bent lead screw, it can also occur due to a crooked Z-axis stepper motor or a loose rod coupler, which connects the lead screw to the stepper motor. Then, bring your printer to its home location (auto home) and change the Z offset value so the nozzle is just above the bed. Once the bed is level, go to the Z offset settings in the tune menu to adjust the Z offset in real-time. How do you reset the Z offset in Ender 3? Lubrication works well for improving movements in your printer. You should also look towards fixing binding issues on your 3D printer by loosening and tightening the right screws. To fix your Z-axis slipping down, you should try tightening your eccentric nuts that hold the X-gantry to the Z-axis. To do this, once more, remove the lead screw from the coupler and try rolling it on a flat surface. Our next fix for Z wobble is to check up on the Z-axis lead screw, which is the motion system that most FDM printers utilize to move the printhead (or bed) up or down. This print quality defect is relatively rare but is no less important to fix. It refers to the appearance of obvious lines on the exterior, typically occurring in regular intervals. Z banding, sometimes known as ribbing, is an issue sometimes seen on 3D prints from FDM printers. Stabilize bearings and rails in other axes/print bed.While Z banding is perhaps one of the more likely results of these two issues, both Z wobble and inconsistent extrusion can also lead to other print quality problems. Z banding is primarily caused by two different phenomenons: Z wobble and inconsistent extrusion. The print in the photo (whose holes are along the z-axis) has stripes along its flank. What does Z wobble look like? Z-wobble is usually spotted when the layers of which the object is printed are not perfectly aligned laterally with their neighbours above and below. Although Z wobble is commonly associated with a bent lead screw, it can also occur due to a crooked Z-axis stepper motor or a loose rod coupler, which connects the lead screw to the stepper motor.

0 kommentar(er)

0 kommentar(er)